Designed and assembled in the USA

When You Can’t Find Workers, Standard Bots Cobots Keep Production Running

Collaborative Robots Built for Real-World Production — Reliable, Safe, and Easy to Deploy

Whether you’re building products, packaging materials, or running small-batch production, keeping up with demand is harder than ever. That’s why Rankin Automation partners with Standard Bots — a new generation of collaborative robots (cobots) built to make automation simple, affordable, and accessible for every type of production environment.

Standard Bots cobots deliver industrial-grade performance without the complexity, cost, or long integration timelines that come with traditional robotics. They’re designed for teams who need reliable help on the floor — not another system to maintain.

Why Choose Standard Bots Cobots

- Fast ROI: Affordable cobots with payback periods often under 12 months.

- Easy to Use: No coding required — intuitive drag-and-drop programming.

- Built to Last: High precision and payloads for industrial environments.

- Safe by Design: Certified for human collaboration, no cages required.

- Flexible & Scalable: Move them, reprogram them, or expand your setup anytime.

Solve Labor and Productivity Challenges Head-On

Staffing shortages. Fatigue. Missed deadlines. Cobots step in where it’s toughest to keep up — doing the repetitive, high-volume, or ergonomically risky work so your people can focus on what matters most.

Common Applications

Machine Tending

Loading and unloading CNC machines can be one of the most repetitive and hazardous jobs on the floor. Standard Bots cobots reliably handle these cycles with precision, freeing operators to focus on higher-value work. With quick-change grippers and safety-rated sensors, they can keep multiple machines running without downtime.

Palletizing

Whether stacking outgoing product or unloading inbound pallets, Standard Bots cobots automate repetitive motion with precision. They keep workflows consistent across shifts, reduce strain injuries, and maintain a small footprint that fits into existing floor space.

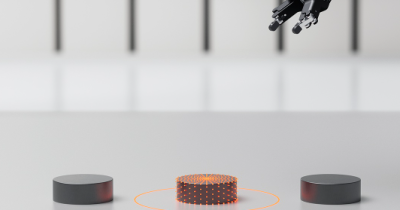

Pick and Place / Kitting

Ideal for repetitive part handling and transfer tasks, Standard Bots cobots sort, pack, and load components between stations with accuracy and repeatability.

Built-in vision and adaptive grip options handle different shapes and materials without constant supervision.

Case Packing / Packaging

From carton erection to final box stuffing, Standard Bots cobots manage packaging tasks with speed and consistency.

They adapt easily to product changes, helping manufacturers and packagers handle high mix–low volume runs without major reprogramming.

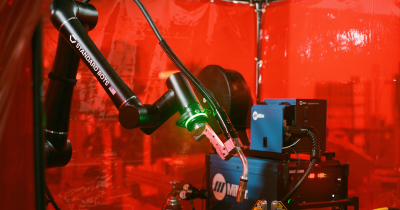

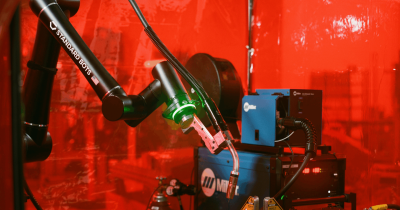

Welding Automation

From tack welds to long seams, Standard Bots cobots integrate seamlessly with MIG and TIG systems to deliver consistent, high-quality welds. Their easy programming interface and torch integration make welding automation accessible to shops of any size — without the complexity of traditional robotic systems.

Inspection / Metrology / Vision QA

Cobots paired with cameras or scanning sensors perform repeatable, high-precision inspections. They track tolerances, surface quality, or dimensional alignment in real time, reducing defects and improving traceability.

Automation in Days, Not Months

With Rankin Automation and Standard Bots, you don’t have to wait months to see results. Our cobots arrive ready to work—quick to install, simple to program, and fully supported by our local integration team. In most cases, customers are up and running in just a few days, seeing measurable gains in productivity, consistency, and labor savings.

Want to understand what that could look like for your operation? Estimate your potential payback or connect with our team to design your first cobot cell.

Use This ROI Calculator to Find Out What a Cobot Will Cost You

Our first cobot was installed and running production in just a few days, and the ROI came even faster than expected. We’re already planning our next installation.

— Operations Manager, Packaging Facility

What Makes Standard Bots Different

| Feature | Standard Bots | Typical Cobot |

|---|---|---|

| Price | ~50% lower entry cost | High upfront investment |

| Programming | Visual, no-code interface | Complex or license-based software |

| Integration | Install and deploy in days | Multi-week setup |

| Flexibility | Modular, mobile, re-deployable | Often fixed post-install |

| Support | Local Rankin Automation team | Remote OEM-only support |

Meet the Standard Bots Family of Cobots

Spark

Payload: 7kg

Reach: 0.95m

Max joint speed: 433°/s

Repeatability: ±0.025mm

Core

Payload: 18kg

Reach: 1.3m

Max joint speed: 435°/s

Repeatability: ±0.025mm

Thor

Payload: 30kg

Reach: 2.0m

Max joint speed: 277°/s

Repeatability: ±0.025mm

Bolt

Payload: 14kg

Reach: 0.95m

Max joint speed: 433°/s

Repeatability: ±0.025mm

Want to Learn More About Cobots?

Discover how cobots can streamline your operations and boost productivity.

Have Questions? Get the Full Scoop Here.

Standard Bots cobots are AI-native and designed for easy programming. They learn tasks through simple demonstration, requiring no coding. These American-made robots are cost-effective, flexible, and can be deployed across a variety of tasks that traditional robots can’t handle.

Anyone can operate Standard Bots cobots! Thanks to their no-code interfaces and demonstration-based programming, cobots are easy to use for people with little to no technical experience. Operators simply show the cobot the task, and it will take over. Training is also available to ensure smooth adoption.

Yes! Standard Bots cobots are equipped with force sensors and collision detection technology to ensure safe interaction with human workers. They meet global safety standards and are designed to work alongside humans in shared spaces.

Standard Bots cobots are versatile and can handle tasks such as assembly, machine tending, quality control,, packaging and much more. They excel in repetitive tasks and complex processes that require precision and reliability.

Standard Bots cobots are designed to increase efficiency by performing tasks up to three times faster than human workers, with greater consistency and reliability. By handling repetitive or physically demanding tasks, cobots free up employees to focus on more complex, higher-value work, improving overall productivity and reducing downtime.

Yes! Standard Bots cobots are highly scalable and can handle both small-batch production and large-scale operations. Their adaptive programming and flexibility make them ideal for businesses of all sizes, allowing you to automate a wide variety of tasks across different production volumes.

From the Blog

Exploring The Versatility Of The Standard Bots RO1 Robot

The RO1 is a versatile robot designed to cater to a wide range of applications showcasing the incredible potential of modern robotics in both industrial and commercial settings. This blog explores how the RO1 robot is transforming critical applications.

American Innovation in Action: The Standard Bots Advantage

At Rankin Automation, we’re proud to offer Standard Bots—a line of collaborative robots (cobots) that are engineered, manufactured, and supported right here in the United States.

New Legislation Makes Cobots an Even Bigger Financial Advantage for Owners and Manufacturers

On July 4, 2025, new legislation was enacted, offering manufacturers a larger financial incentive to embrace automation.

Maximize your Operational Potential with Standard Bots Collaborative Automation Solutions

Speak with a Dedicated Rankin Represenative

Rankin has developed an extensive product offering through partnerships with industry leading manufacturers. With extensive experience in the industry, count on us to meet your needs while improving your facility’s operation and efficiency.

Need to speak with someone immediately? Call us.

610-544-6800